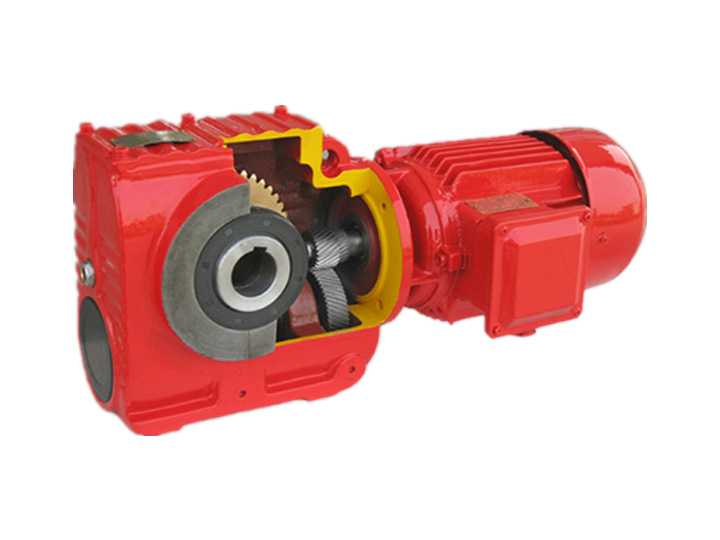

S series helical worm gear reducer

Classification: S series helical worm gear reducer

Overview: I. Overview:1. This series of reducers is designed and manufactured on the basis of the modular combination system, and there are many motor combinations, installation forms and structural schemes. The transmission ratio is finely divided and has a wi…

InquireI. Overview:

1. This series of reducers is designed and manufactured on the basis of the modular combination system, and there are many motor combinations, installation forms and structural schemes. The transmission ratio is finely divided and has a wide range, and the combined model can form a large transmission ratio. It can meet different working conditions and has superior performance.

2. This series adopts an integral casting box, which has good structural rigidity and is easy to improve the strength of the shaft and the life of the bearing. The key parts of this series are made of high wear-resistant materials and undergo special heat treatment, which has the characteristics of high machining accuracy, stable transmission, small size, large bearing capacity, and long service life.

3. It can be used for forward and reverse rotation, bear large radial load, and can bear axial load not greater than 10% of radial force. It is widely used in metallurgy, sewage treatment, chemical, pharmaceutical and other industries. "

2. Features:

1. The output shaft of this series is perpendicular to the input shaft, and the transmission part is composed of helical gears and worm gears.

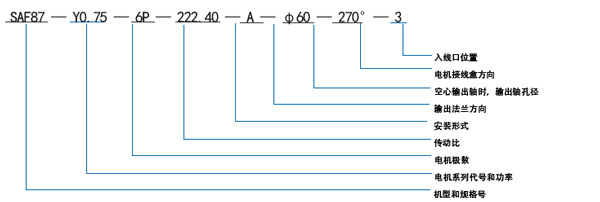

2. Installation method: foot shaft extension installation (S type), B5 flange shaft extension installation (SF type), hollow shaft installation (SA type), flange hollow shaft installation (SAF type), B14 method Blue hollow shaft installation (SAZ type), hollow shaft installation with anti-rotation arm (SAT type). The installation position is not limited and it is easy to choose.

3. The reduction ratio 7.5-69.39 is 77%; 70.43-288 is 62%; the S/R combination is 57%.

4. Low noise: The main parts of the reducer have been precisely machined and carefully assembled and tested, so the noise of the reducer is low.

5. Long service life: under the conditions of correct model selection (including selection of appropriate service factor) and normal use and maintenance, the service life of the worm gear part is not less than 10,000 hours, and the service life of other main parts (except wearing parts) Generally not less than 20,000 hours. The wearing parts include lubricating oil, oil seals and bearings.

3. The model and related parameters of the reducer:

| Specification | 37 | 47 | 57 | 67 | 77 | 87 | 97 | |

| structure type | S SA SF SAF SAT SAZ | |||||||

|

input power

(kw)

|

0.18-0.75 | 0.18-1.5 | 0.18-3.0 | 0.25-5.5 | 0.55-7.5 | 0.75-15 | 1.5-22 | |

| gear ratio | 10.27-165.71 | 11.46-244.74 | 10.78-196.21 | 11.55-227.20 | 9.96-241.09 | 11.83-223.26 | 12.75-230.48 | |

|

allowable torque

(N.m)

|

90 | 170 | 300 | 520 | 1270 | 2280 | 4000 | |

| weight(Kg) | 7 | 10 | 14 | 26 | 50 | 100 | 170 | |

-

2022-03-10 15:52:45

With the rapid development of modern production technology, more and more high-tech products have been put into use. The …

-

2021-12-23 15:55:21

When there is a problem with the gear, we need to take corresponding methods to deal with it. If it is not serious, then …

-

2021-11-18 15:56:43

ZLYJ reducer is a very common transmission device. In the machinery industry, ZLYJ reducer is widely used. The reason why…

-

2021-10-21 16:27:54

The role of gear transmission on mechanical equipment is very important, but sometimes there will be problems with gear t…

-

2021-09-16 08:31:20

The extrusion compound machine system plays a very important role in production. Although it has a great effect, many use…

-

2021-08-19 15:57:52

When using a high-speed mixer, you must follow the correct steps to operate it. If you do not pay attention during the op…